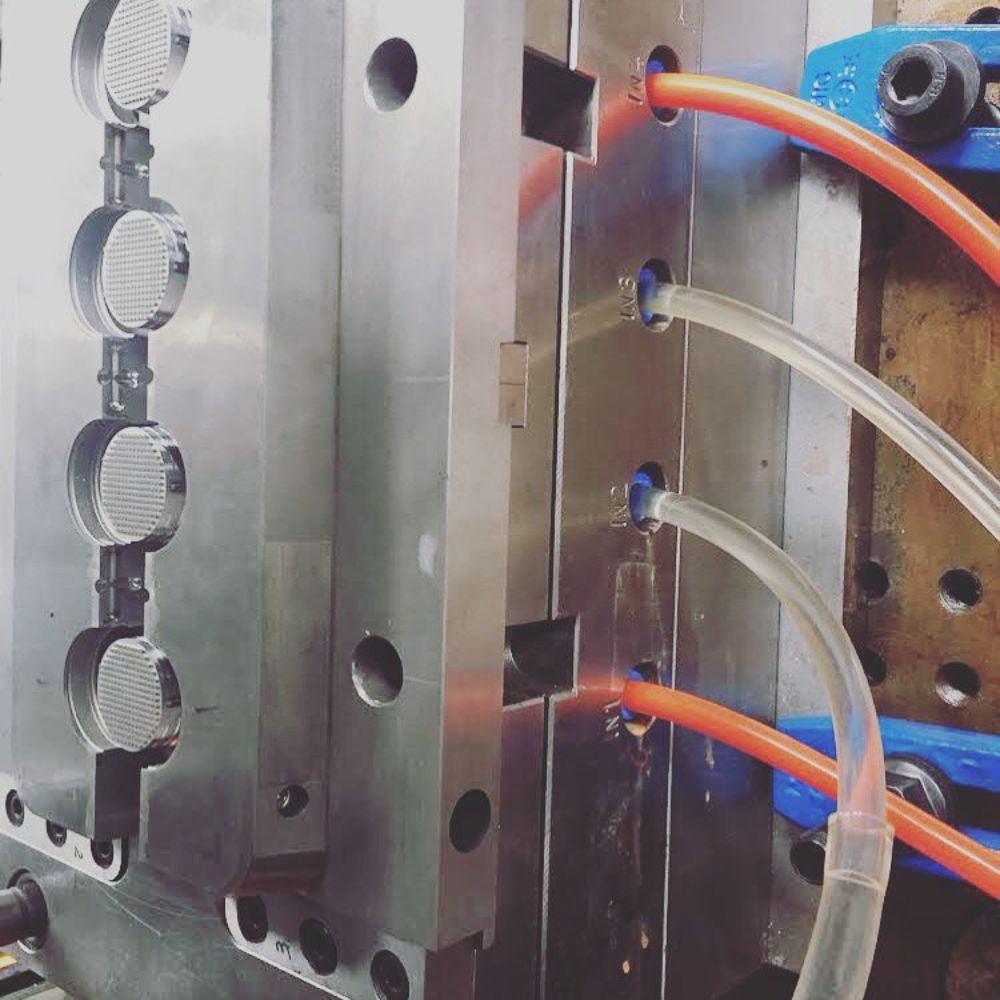

Tooling is the mould used to create a plastic product. Often a very large block of steel that is machined out to have the negative profile of the end plastic parts. Tools can have moving parts and multiple cavities. They are very complex as they also have integrated cooling and multiple feed points.

Tooling costs vary dramatically depending on the size and complexity of the part. For example a small one piece product with a simple 2 part tool could cost around £3,000, whereas a very large complex product with multiple pieces could be up to £500,000. An average product will cost about £50,000 for tooling. Time scales for tooling will be around 6 – 12 weeks.