Prototyping is integral to the design process, a practice that Centreline employs throughout every project at multiple stages, to ensure optimal outcomes for our clients. These prototypes range in complexity, spanning from sketch and form models, to functional test rigs and polished presentation models. They enable our team to validate designs through rigorous testing, bridging the gap between concept and realisation.

What is Prototyping?

Prototyping in a wider context, is an iterative process implemented by designers to allow for the testing of a design, providing valuable feedback that may help identify potential issues before moving to full-scale production. It allows us to directly observe the design in three dimensions. Below are some of the various types of prototypes that we employ:

Research prototyping

Concept prototyping

Engineering prototyping

Presentation prototyping

Research prototyping:

During the research phase, we create proof of principle low fidelity models, focusing on specific aspects which could significantly impact the design direction. The purpose of this is to allow both our clients and designers to gain a more informed insight by validating decisions, which will help guide and steer the project direction.

Concept Prototype:

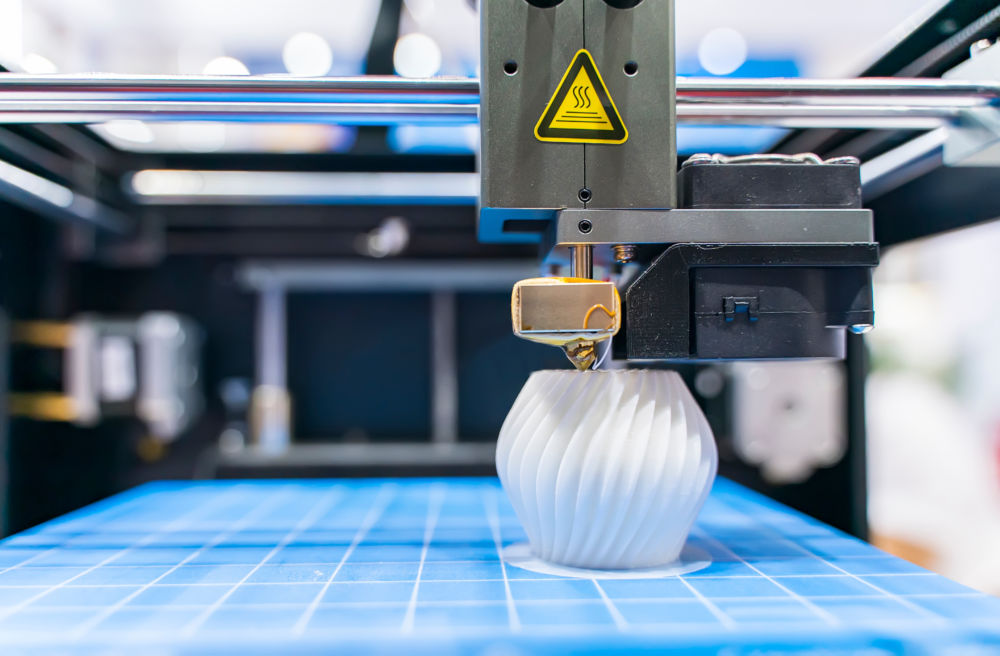

‘Sketch modelling’ is implemented into the concept stage, allowing our clients and team to get hands-on with a tangible, size appropriate 3D form. These prototypes can be rudimentary, constructed from simple materials such as card, to being created using more advanced techniques including foam modelling and CNC machining, through to additive manufacturing processes (3D printing). This process helps progress the project efficiently and all findings feed directly into the engineering phase of the project.

Engineering Prototype:

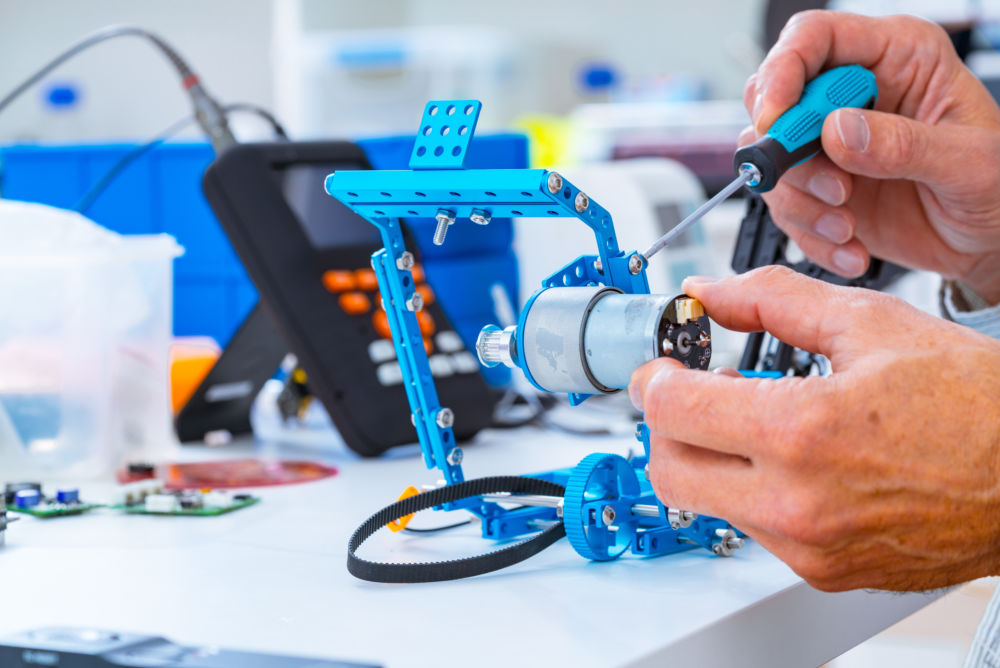

Engineering prototypes represent the form, fit and function of the product. They allow for a deep appreciation and understanding of any challenges that may be present, which can be ironed out before the significant investment of the production stage. Specific aspects of the design (such as mechanisms, technology and subsystems) can be tested, ensuring that the solution is practical and viable.

Presentation Prototype:

Highly detailed presentation models can be produced that replicate the form, finish and detailing of the design. These prototypes are specifically designed to represent a production unit as close as possible; it is a near-final representation of the product, sometimes demonstrating partial (and less commonly full) functionality. They are ideal for sharing with invested parties and focus groups, providing investors and potential investors with a tangible product. Presentation prototypes can also be used in promotional imagery/videos for marketing purposes.

At Centreline, we consider prototyping an essential tool for successful design development and as such, we seamlessly integrate it throughout our design process. It enables us to confidently create viable solutions to our clients' challenges. It promotes an iterative design process, offering numerous opportunities for feedback.