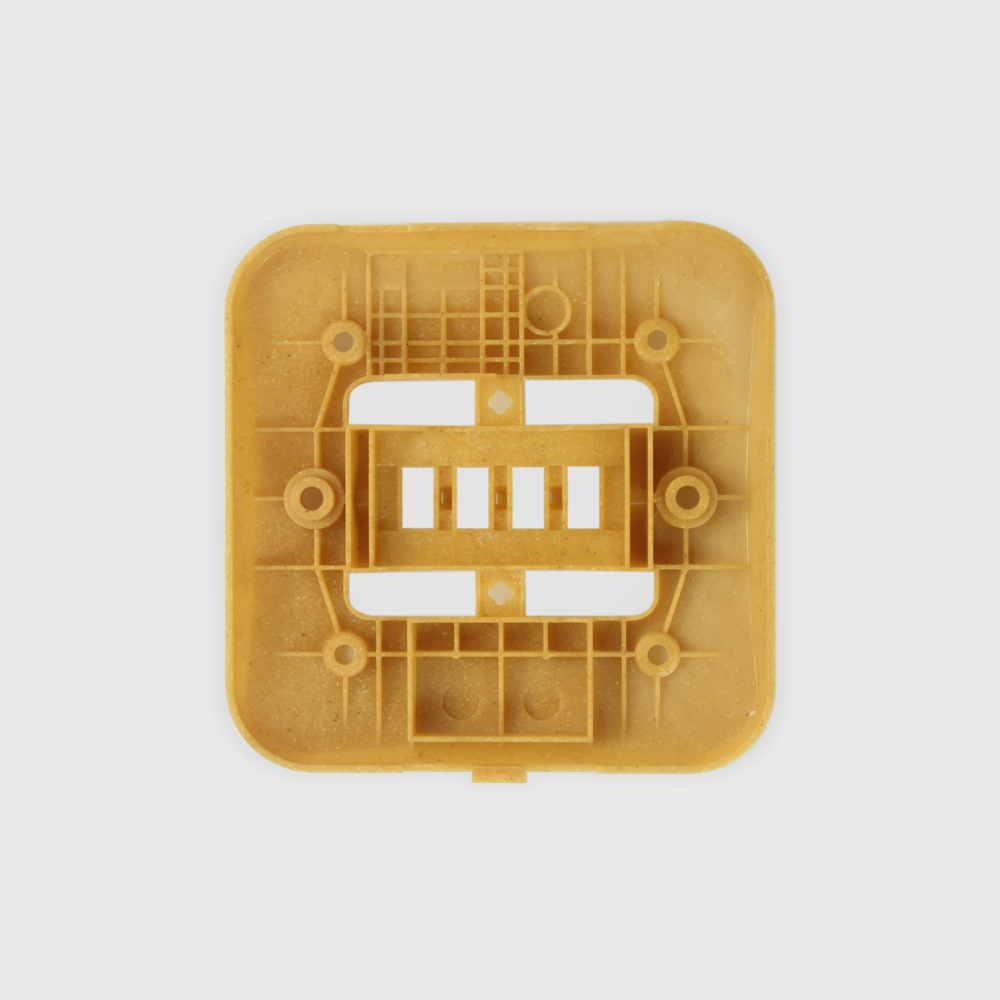

We’ve started off the new year by continuing our exploration into eco/ environmentally conscious materials. We’re really passionate about the impact we can have as designers on the decisions surrounding product end of life and material selection. We’ve noticed a real surge in eco plastics interest and we’re working hard to further understand the potential appropriate application and limitations of these. The more informed we are, the better equipped we are for making decisions and proposing the use of a more environmentally conscious approach to design. Below is just a small section of biodegradable plastics/ eco-materials we’ve been trialling, each come with their own unique aesthetic and challenges.

Sulapac -

Pros:

- Biodegradable

- Completely free of micro plastics

- Suitable for injection moulding

- Food safe

Cons:

- More suited for chunkier wall thicknesses

- Limited colour range

- High stiffness = More brittle

PLA -

Pros:

- Biodegradable

- Non toxic incineration

- Suitable for injection moulding

- Food safe applications

Cons:

- Limited colour range

- Brittle, poor durability and impact resistance

- Low heat resistance

- Tailored towards single use items

Bamboo -

Pros:

- Biodegradable

- Natural aesthetic

- Sheet/ Block format

- Minimal upfront investment

Cons:

- Machinable, can’t be moulded

- Removing material from blanks produces waste (which can be used as filler in eco plastics)

- Fabrication can be expensive

- Anthony