Developed for Scalemaster® the i-Test® is an app controlled water quality testing kit designed for the plumbing industry to reliably check if a central heating system is adequately protected from corrosion. The i-Test's intuitive and user friendly operation is designed to fit within the on-site routines and environments of heating engineers. This user centred design intent enables the test to be conducted quickly and consistently, prolonging the life of heating systems with minimal time and cost investment.

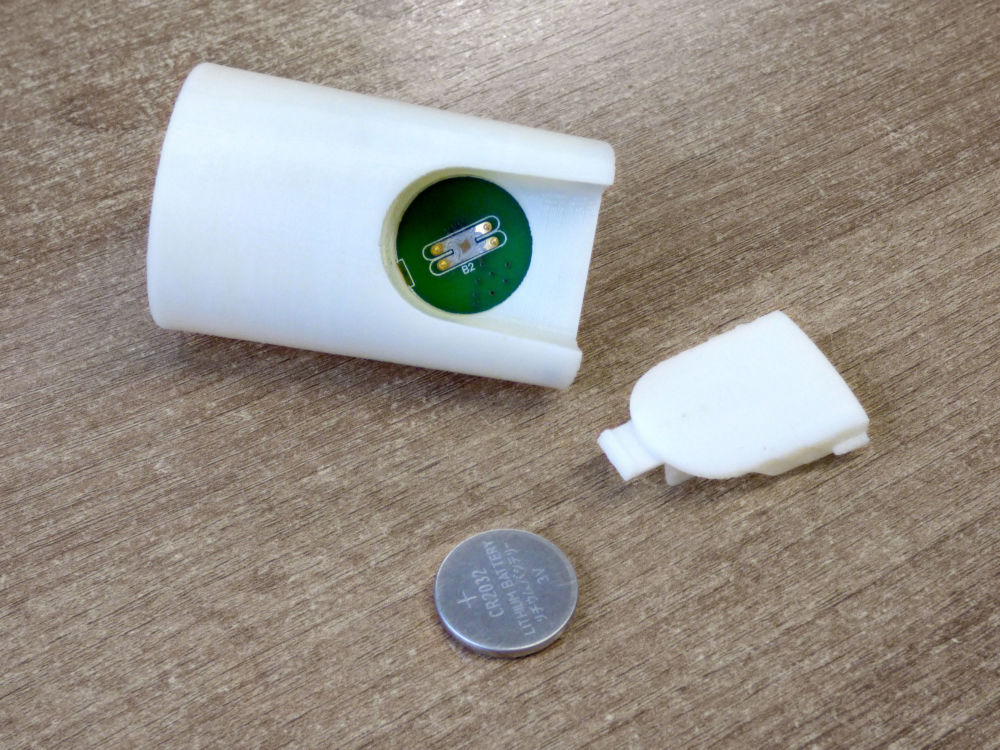

PROVING PRINCIPAL

Seeking

to overcome the shortcomings of existing test procedures, Scalemaster® identified a unique testing method utilising dissimilar metals to

identify the levels of chemical inhibitor present in a central

heating system. Together with IZEapps, Centreline were initially

approached to help the client further validate the technology by

designing a practical means of developing and evaluating the test

method. Following refinement of the technology and proof of the

principal, a conceptual design phase was undertaken to develop the

system into a self contained portable and wireless testing kit. The

primary design intent being to ensure reliable test results through

controlled test conditions. This led to a user centred design

approach focusing on making the test procedure as user friendly and

intuitive to operate in a consistent and controlled manner,

eliminating

user error and environmental variables that could affect test

results.

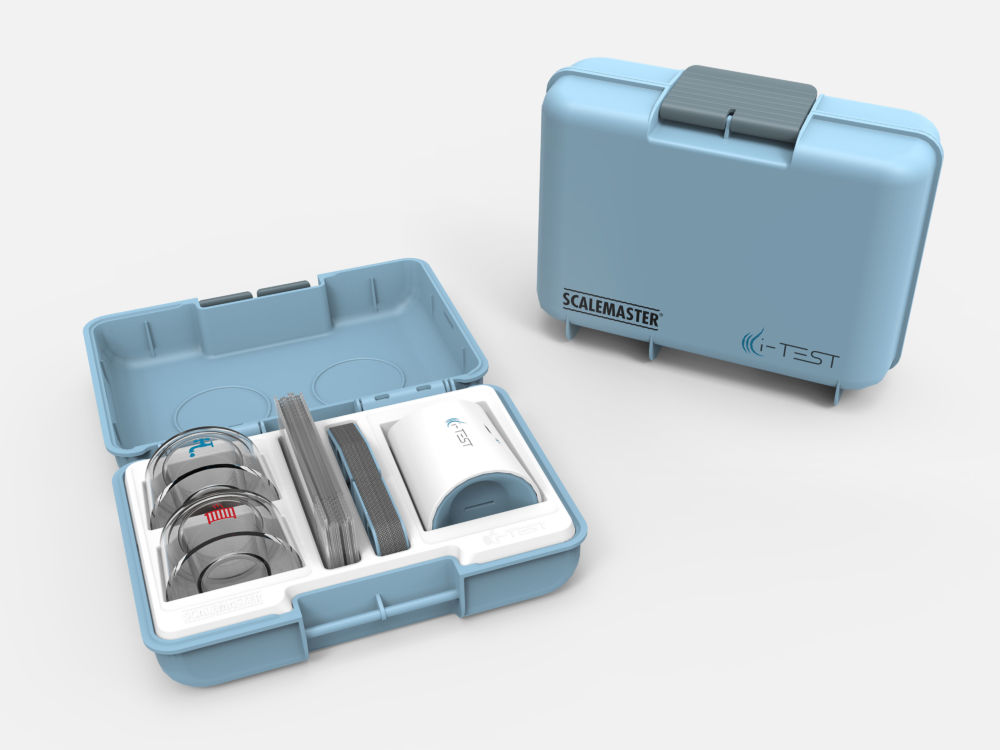

INDUSTRY FOCUSED

To better understand the conditions of the operator, Centreline were commissioned to design and produce a batch run of prototype kits. These were distributed to a user group of practiced heating engineers to gather test data and evaluate the design of the i-Test® kit in practice. After several months of study user comments and data were passed onto IZEapps and Centreline to inform the next phase of product and app development. This led to a refreshed design and rebrand of the i-Test® to better suit the current design trends and requirements of the industry. The product and packaging was taken through an iterative development and evaluative design process to build innovation into every aspect of the design. Focusing on portability, durability and ease of guaranteeing consistent test procedure the design was tailored to the industry. Following refinement further prototypes were produced to successfully validate and approve the final design.

TRUSTED MANUFACTURE

After choosing to manufacture through Centreline and our trusted suppliers the production tooling for the i-Test® was arranged and commissioned. Benefiting from our experience and close working relationship with our suppliers a sampling and quality control refinement process ensured the end product was produced fit for purpose minimising risks and delays and ensuring all aspects of the design intent were maintained through the manufacture process. Centreline have since successfully delivered the first production run and continue to support Scalemaster® with marketing material for the i-Test®.

- Shane